Infrastructure & Manufacturing

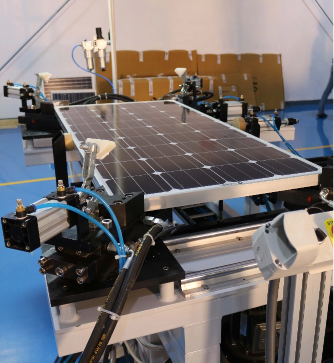

Bluebird Solar houses a 1.2 GW Fully automated and advanced manufacturing facility that has provided solar panels to residential, commercial, and industrial customers with the best quality PV modules. Our products demonstrate innovative technology and match the globally accepted quality, longevity, performance, and environmental sustainability standards.

Infrastructure &

Manufacturing

Bluebird Solar houses a 300MW automated and advanced manufacturing facility that has provided solar panels to residential, commercial, and industrial customers with the best quality PV modules. Our products demonstrate innovative technology and match the globally accepted quality, longevity, performance, and environmental sustainability standards.

Quality-oriented Manufacturing

We ensure optimum quality is maintained, right from the raw materials we choose to the actual manufacturing of solar panels. As a result, our solar photovoltaic modules achieve maximum possible efficiency and output.

We use ‘A’ grade solar cells and other raw materials sourced from Tier one suppliers. Since the process and quality control determine solar panels’ life, our production team stringently examines every item used in manufacturing.

Facilities At Factory

Fully automatic conveyorised system

for Material Movement

100% Visual inspection Pre and

Post lamination

System from

Consul

Screw Type Air-compressor coupled with

Refrigerated Air Dryer from ElGi

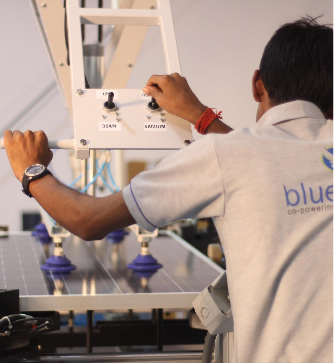

Automatic hydraulic framing machine with crimping feature for robust frame locking

100% Power-backup through

UPS and generator

Fully automatic conveyorised system

for Material Movement

100% Visual inspection Pre and

Post lamination

System from

Consul

Screw Type Air-compressor coupled with Refrigerated

Air Dryer from ElGi

Automatic hydraulic framing machine with crimping

feature for robust frame locking

100% Power-backup through UPS

and generator

Solar Panel Manufacturing Process

Cell Testing & Cutting

01

Solar cells are checked and inspected using adva nced optical or imaging sensors to ensure all the components are located correctly. The cells’ very delicate wafers are not damaged or cracked. Further, with the help of a laser machine, they cut into different dimensions depending on the wattage of the Solar Panel. Cutting is skipped where a full-size cell is required.

Tabbing & Stringing

02

The first step i s tabbing and stringing to make a solar cell array. Multiple ribbons are first soldered to the front and back surfaces (tabbing) after tabbing the stringer subsystem, which solders the front side ribbons of a first PV cell to the backside ribbons of the neighbouring PV cell to form strings of PV cells wired in series.

Lay-up & Bussing

03

In this process, the solar ce ll strings from the stringer are placed on the layup table above EVA-covered glass. A small piece of adhesive tape is applied to the cells to hold them in place. This process is called lay-up. Now the second layer of the EVA sheet, the polymer back-sheet, is placed on the solar cell array. The bus wire is soldered with tab wires.

Visual Inspection

04

Visual inspecti on of a PV module is performed before the module has been subjected to environmental, electrical, or mechanical stress testing in the laboratory. This visual inspection is done by looking at the glass underneath to check the PV module alignment, cell-matrix and presence of dust particles or another element on the cell.

Electroluminescence Testing

05

Bluebird solar panels are 100% EL tested. Electroluminescence technology enables us to iden tify the defects in the modules that are invisible otherwise. These defects may include cell damage /microcracks in the inner structures of the solar cells that can cause underperformance or hot spots in the future. This also checks inactive strings, cell breakage and fissures.

Lamination

06

The encapsu lation of the solar cells through lamination is a crucial step in solar panel manufacturing. It ensures the longevity of the solar cells of the PV Module. The prepared 5-layer module is placed in the lamination machine and heated to the max during the lamination process. 135°C for 20 -25 minutes. The laminate that comes out is completely sealed and is left for 10-15 minutes to cool down till it reaches room temperature.

Framing

07

Solar panel framing refers to the pro cess of attaching protective and strengthening aluminium frames to the PV laminates of a solar panel. The frame that slides around the laminate will be filled with silicon adhesive. Then, the frame will be pressed around the laminate. The holes on the back of a PV frame make it easy to install the panels on a mounting structure

Sun Simulation Testing

08

Sun SimulatorTest or Flash Test measur es the output performance of a solar PV module. During a flash test, the PV module is exposed to a short (1ms to 30ms), bright (100 mW per sq. cm) flash of light whose output spectrum is as close to the spectrum of the sun as possible. Module parameters are measured at standard test conditions (STC). The flash test results are compared to the data specifications of the PV module type, which are then printed on the label and pasted at the back of the solar panel

Fixing Junction Box

09

An IP68 rated PV junction box is attached to the back of the solar panel with silicon adhesive. It is the output interface of the solar panel. The diodes inside the junction box keep the power flow going in one direction and prevent current from feeding back into the panels when there's no sunshine. It is connected to MC4 connectors with the help of 4mm cables.

Join Our Newsletters.

Get Offers & Updates To Your Inbox